Introduction: The Beginning of a Legacy

In the heart of the Canadian prairies, a small welding operation founded over four decades ago has grown into one of North America’s leading trailer manufacturers. Southland Trailers, a trailer manufacturing company that started in a modest garage, has transformed into a powerhouse of innovation, quality, and efficiency. A blue-collar welder perfected his craft and built a formidable trailer manufacturer based on teamwork and a commitment to continuous improvement.

We delve into the fascinating history, culture, and advancements of this remarkable trailer manufacturer.

Chapter 1: Humble Beginnings

Southland Trailers began as a small operation in 1980, founded by a clever welder named Monte Sailer. Working at another factory at the time, Monte saw an opportunity to improve the manufacturing process and decided to go out on his own. With his wife Shelly going door-to-door to secure welding contracts, the couple slowly began to expand. Initially, they built frames for other trailer manufacturers, but as the demand for quality grew, they started building entire trailers.

What started as a side hustle became a full-fledged business as Monte and Shelly’s sons took over, bringing fresh energy and ideas to the company. Today, Southland Trailers produces between 80 and 90 trailers daily, operating on 37 acres with 560 employees, all while maintaining the family-oriented culture that started it all.

“The whole world is built on blue collar labor. There’s no doubt about it. The house you’re sitting in, the phone that you’re talking on, the car you’re driving: all blue collar.”

Chapter 2: The Culture of Continuous Improvement

At the heart of Southland’s success is a deeply ingrained culture of continuous improvement. This principle isn’t just a catchy phrase on a wall; it’s a daily practice embraced by every employee. From the factory floor to the boardroom, every team member is encouraged to identify areas for improvement in their work environment and processes.

The company’s morning huddle is a testament to this culture; these huddles involve small teams gathering to discuss goals, strategies, and the previous day’s successes and challenges. The day ends with a quick meeting to discuss what went well and what can be improved.

This focus on continuous improvement extends beyond the factory floor. Southland encourages personal growth and development among its employees, offering training programs through what they call “Southland University.” These programs cover everything from technical skills to personal development, helping employees become better craftsmen and better people.

“It starts on the shop floor. It just becomes part of the culture.”

Chapter 3: Efficiency and Innovation in Trailer Manufacturing

One of the most striking aspects of Southland Trailers is its ability to constantly improve trailers while reducing their overall cost. Take, for instance, the Southland 270 7×14 14K dump trailer. From 2015 to 2024, the price of the 270 increased 8% which is about one fourth the inflation rate of about 33%. Even with all the improvements and upgrades on the 270 over the years, the price to the operator is more attractive today.

Southland achieves this by constant improvement through teamwork. Work smarter, not harder. Share best practices. Ideas from the people on the ground and feedback from the users. Today, the company produces 21 of these trailers daily, compared to just two per day back in 2015.

“When our workers identify efficiencies that enable them to complete two more trailers per day, we just pass the cost savings on to our customers.”

Chapter 4: Superior Trailer Performance Through Engineering Excellence

Southland Trailers makes the correct choices, even when they go unnoticed. Ultimately, Southland makes a tough trailer as light as possible to maximize payloads. Let’s highlight a few of Southland’s designs and strategies that are unique amongst trailer manufacturers.

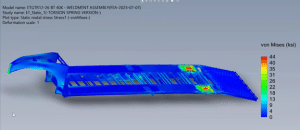

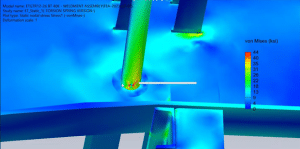

- Finite Element Analysis (FEA). Southland Trailers analyzes every trailer, every joint, every weld. When you can identify specific areas of concern, you can make small changes to the design without adding a bunch of extra weight. How many trailer manufacturers use liquid cooled GPUs to test trailer loads under static and dynamic scenarios?

In this example, an FEA analysis on a Gooseneck Flatbed shows a weak spot that needs engineering input:

In this example, this cross brace (the size of a quarter) is showing a potential stress point that will be redesigned before production:

- Hardened Steel. Hardened Steel is expensive and requires sophisticated processing equipment and techniques, which is why most trailer manufacturers avoid it. Think rifle barrel vs. an automotive body panel. Southland Trailers uses Hardened Steel to maximize the trailer capabilities and longevity while minimizing the weight – which enables higher payloads. We all know larger payloads means more revenue for operators.

- Custom Engineered Steel Beams are Better Than I-Beams. You don’t see semi-trailers built with stock I-Beam frames. Southland Trailers has brought long haul trucking designs to utility trailers by making their own Custom Beams (Engineered Beams) with hardened steel. Stock I-Beams provide the same strength along its length (e.g., 12# or 14# per foot of mild steel vs. 30,000+ # per square inch for Hardened Steel); you need different strength across a frame and stock I-Beams add unnecessary weight across the entire frame.

This image shows a Custom Beam (the Flange and Web are both Hardened Steel, unfinished) that uses axles to support the Custom Beam. This design 1) decreases the weight to increase the payload, and 2) lowers the trailer bed and the payload’s center of gravity for better driving performance. Typical I-Beams raise the bed height and add unnecessary weight (unless you weld and cut the I-Beam, which is a bad idea).

This image shows another Custom Beam (Engineered Beam, unfinished) of Hardened Steel under a dump bed. Similarly, the weight and performance is superior to multiple I-Beams and multiple cross members. You’ll find this Engineered Beam on their smallest 5×10 dump trailers, 6×12 dump trailers, 7×14 dump trailers, and all the way up to their giant gravel boxes.

This Southland 5×10 10K dump trailer, one of the smallest in their dump lineup, weighs about 2,700 pounds, has a GVWR of 11,440 pounds which enables a whopping 8,770 pound payload. All at an affordable price that makes it possible for a homeowner to own a trailer worthy of a hard-core commercial contractor. Southland Trailers brings technology of the giant gravel boxes to the professional grade utility market.

One more Engineered Beam example which shows Southland’s commitment to excellence all the way down to their accessories. This image is a 12-gauge steel (Hardened Steel, galvanized) ramp that uses an Engineered Beam to enable a 4,500# mid-span rating. If you don’t appreciate the engineering and performance, you will certainly appreciate the weight when you lift the ramp and move it around. If you want to be even more impressed, then upgrade to Southland’s aluminum ramps.

Do NOT try this at home:

- Borrowing From Long Haul Roots. All of this fancy engineering is borrowed from Southland’s experience in the long haul trucking and heavy construction products. Southland’s Renn line of long haul trucking has decades of experience and millions of miles tested against demanding Canadian conditions. Look at any gravel box, large dump truck, long haul semi-trailer and you will see the same designs found in Southland’s smallest professional utility grade trailers.

Image: Southland RENN SLDD-53 Drop Deck (cambered)

- HSS Hollow Structural Section Tubular Hardened Steel. Again, Southland goes the extra mile. HSS tubes for pipe bracing and pierce beams underneath the trailer. We’ve discussed Hardened Steel, but the HSS tubes are again far superior to I-Beams which surprisingly flex and twist.

- HD Fir Decking. Southland uses premium non-dimensional 2×6 and 2×8 high density fir. HD Fir is very dense, compared to spruce or pine, and performs well in all conditions. If you have ever tried to back out a screw from HD Fir, you know exactly how durable and resilient it is.

“Other manufacturers use mild steel and just keep adding cross beams until it doesn’t bend. It works but it increases the trailer weight, which decreases the payload. At the end of the workday, the payload is where operators make their money.”

Chapter 5: The Role of Robotics and Technology in Modern Trailer Manufacturing

As Southland Trailers has grown, so too has their reliance on advanced technology and robotics. These tools have allowed the company to increase production capacity without sacrificing quality. One of the most significant advancements is the implementation of robotic painting systems. These systems not only improve the consistency and coverage of paint but also allow for quick color changes, making the production process more flexible and efficient.

The introduction of robotics has also impacted the workforce at Southland. Contrary to the common belief that robots replace human jobs, at Southland, each new robot requires eight blue collar workers. For example, the robotic laser used to cut steel sheets operates around the clock, but it requires a team of people to feed it raw materials and quality check the output. This synergy between humans and machines has been a key factor in the company’s success.

But it is still about the blue collar workforce. Fewer heavy lifts and injuries. Fewer mind warping repetitive tasks.

“Robots are also about protecting our workforce. Nobody wants to, or should, dress up for a Mars landing and crawl into a paint booth every day.”

Chapter 6: Environmental Considerations and Quality Control in Manufacturing

Facing some of the harshest weather conditions in North America, Canada-based Southland Trailers requires a focus on building trailers that can withstand extreme cold, wet environments, mountainous terrain, and salt exposure. The result is a line of trailers that are approved by Mother Nature.

For example, Southland uses Pittsburgh Paint and Glass (PPG) paint coatings and is regularly audited to ensure Southland meets the highest environmental and quality standards. Every trailer is steel shot blasted before painting, ensuring that the paint adheres properly and provides long-lasting protection. This attention to detail has paid off; during a major flood in the Fraser River area, over 100 Southland Trailers were submerged, yet, six months later, these trailers were on the road, having required only minor electrical maintenance. Shocking durability? We think not.

“Our use of advanced materials ensures that our trailers can withstand the rigors of daily use, whether you’re hauling heavy equipment or enduring harsh weather conditions. Our trailers have decades of exposure to the harsh Canadian mountains and the hot salty climate of Florida.”

Chapter 7: Personal and Team Growth Initiatives

Consistent trailer manufacturing quality and durability require engaged and caring employees. As a result, Southland places a strong emphasis on the personal growth and development of its employees. The company runs quarterly initiatives designed to foster a positive work environment and encourage team members to set and achieve personal goals. One such initiative was the “Random Acts of Kindness” campaign, where employees earned points for helping others, whether within the factory or in the broader community.

Southland Trailers routinely supports internal goals, encouraging employees to work together to achieve targets like increasing daily steps, drinking more water, or reading more books. This holistic approach to employee well-being is part of what makes Southland a unique and successful company.

“Ultimately, it is about our people. We provide training for career development that improves the lives of our valuable employees, inside and outside work.”

Chapter 8: The Future of Southland Trailers

To ensure a bright future, Southland Trailers continues to focus on innovation. The company’s commitment to quality, efficiency, and continuous improvement has positioned Southland as a leader in the trailer manufacturing industry. With a strong foundation built on family values, employee development, and innovation through technology, Southland is well-equipped to meet the challenges and opportunities that lie ahead. Whether you’re in the market for a small utility trailer or a large, heavy-duty hauler, Southland Trailer’s products stand out for their engineering excellence, durability, and the unique culture that goes into every trailer they build.

Chapter 9: Southland Trailer Spotlight:

The Southland 270 7×14 14K Dump Trailer was a game changer when it was first introduced in 2015 and it has only gotten better. It has one of the highest payload to dry weight ratios in its class and includes all of Southland’s clever engineering. Recently, many manufacturers have tried to imitate the SL 270, so pay attention to the details: dump wall with breaks (not straight, smooth walls), Engineered Beam vs. C Channel frame, 2×6 HD Fir sideboards, HSS tubular hardened steel vs. mild steel, etc. The difference is in the details.

This image is a Southland 270 7×14 14K dump trailer ready for work:

The Southland 7×16+2 V-Nose 7K Cargo is a popular cargo in our lineup. The V-Nose adds extra storage and improves aerodynamics and handling. It has VHB Bonded Sides and an automotive undercoating. Again, all of Southland’s clever engineering is built into the trailer.

A quick story about one of Southland’s loyal customers. High winds blew over their cargo while under tow, sending it off the road and through a barbed wire fence and several posts. After replacing the VHB panel on the front VHB quarter panel and replacing the fender, the cargo was back on the road. No frame bending or structural damage. This shows you how strong HSS Tubular Steel really is.

Of note:

1” on 1” top rail

Fully enclosed wiring (you can do that with HSS tubular steel)

16” OC cross members

¾” Plywood Floor, 3/8” plywood walls

Like all Southland trailers, Southland Cargos are built to last.

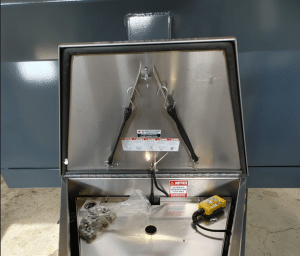

Details matter. Let’s quickly look at Southland’s toolbox. Designed in house. Fabricated in house.

- Doesn’t rust. Lightweight to increase the payload.

- Braces under the lid to handle an operator standing on it.

- Shelf for tools and to protect the battery, pump, and electronics.

- The light is on a mercury switch so you don’t have to worry about killing your battery.

The coolest: the hinge is cut into the lid piece and into the rear box piece so there is no hinge-connection problems.

“So if someone says it looks a little bit homemade, it is. We want it to last forever”

Conclusion: A Legacy of Trailer Manufacturing Excellence

Southland Trailers is more than just a manufacturer; it’s a company built on a legacy of hard work, innovation, and a relentless pursuit of excellence. From its humble beginnings in a small garage to its current status as a leader in the trailer industry, Southland continues to set the standard for what a family-owned business can achieve. As they look to the future, one thing is certain: Southland Trailers will continue to lead the way in quality, innovation, and customer satisfaction. Trailer Station USA is proud to represent Southland Trailers as a Dealer. Visit our website or a Washington or Oregon trailer dealership near you to learn more about Southland Trailers or to purchase one today.